Trusted company that deals in quality-made products

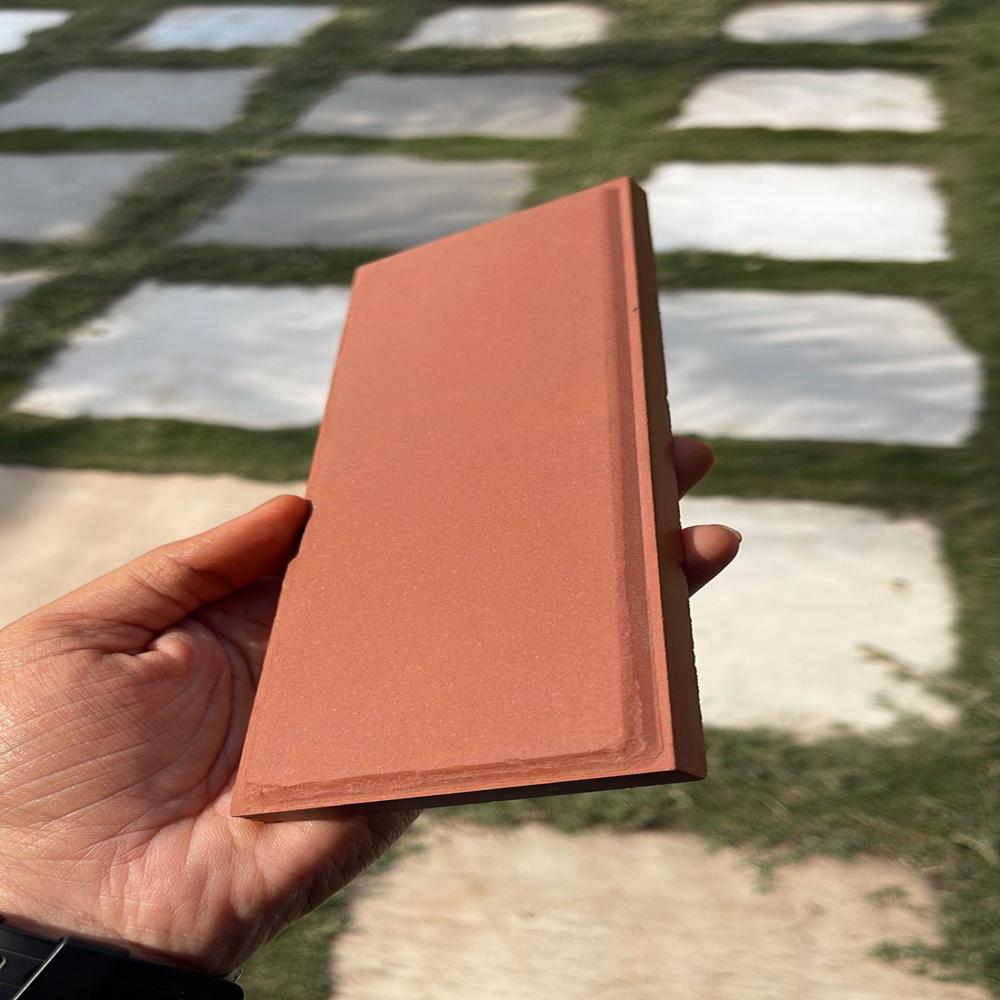

Basic Refractory Bricks,

50.0 INR/Piece

Product Details:

- Water Absorption 10%

- Working Life 20 Years

- Compressive Strength 15-25 Megapascals (MPa )

- Dimension (L*W*H) 9*3 Inch (in)

- Bricks Type Refractory Bricks

- Click to view more

X

Basic Refractory Bricks, Price And Quantity

- 1000 Piece

- 50.0 INR/Piece

Basic Refractory Bricks, Product Specifications

- 9*3 Inch (in)

- Brown

- Fire-retardant, Fire Brick

- Rectangualr

- Other

- 15-25 Megapascals (MPa )

- Refractory Bricks

- 20 Years

- 9*3 Inch

- 10%

- Engineering Bricks

- Standard

- Natural Slate

- Solid

Basic Refractory Bricks, Trade Information

- Mundra Port

- Cash in Advance (CID)

- 1000 Piece Per Month

- 7 Days

- Yes

- Free samples are available

- Box Pack

- Central America

- All India

- Focused on Environmental Management, ensuring the mining and production of chromite (which can be toxic if mismanaged) follow environmental laws.

Product Description

mitticool

Basic refractory bricks are high-temperature, alkaline-based materials designed to withstand harsh environments in furnaces, kilns, and steelmaking processes. They are primarily composed of magnesia and dolomite, offering excellent resistance to basic slags, corrosion, and high temperatures, typically from (1400) to (2100) degrees Celsius, making them crucial for lining metallurgical furnaces and other industrial applications.Superior Fire Retardant Capabilities

Our basic refractory bricks are engineered to resist high temperatures and flame exposure. Manufactured from natural slate, the bricks deliver outstanding fire-retardant properties, making them an ideal choice for industries where heat resistance is critical, such as steel, cement, and glass plants.

Consistent Quality with Standard Sizes

Offered in standard dimensions and solid construction, our bricks ensure uniform application in diverse industrial settings. The rectangular shape facilitates easy installation and consistent performance in building robust furnace linings and other refractory structures.

FAQ's of Basic Refractory Bricks,:

Q: How are basic refractory bricks manufactured using natural slate?

A: Basic refractory bricks are produced by processing natural slate into a fine mixture, which is then molded into standard rectangular shapes and fired at high temperatures. This method enhances their durability and fire-retardant capabilities, resulting in a solid, heat-resistant product.Q: What are the main applications of these refractory bricks?

A: These solid brown refractory bricks are primarily used in constructing industrial kilns, furnaces, and heating chambers, where high thermal resistance, structural stability, and reliability are essential for operational safety and efficiency.Q: When should I choose fire-retardant refractory bricks for my project?

A: Fire-retardant refractory bricks are recommended whenever your project involves exposure to extreme temperatures, such as in metallurgical factories, glassworks, or cement plants, ensuring protection and long-term performance.Q: Where are your basic refractory bricks manufactured and supplied from?

A: Our refractory bricks are manufactured in India and supplied both domestically and internationally, guaranteeing reliable sourcing and timely delivery for diverse customer requirements.Q: What process is involved in exporting refractory bricks?

A: As an exporter, we follow stringent quality checks, secure packaging, and efficient logistics to ensure our fire-retardant bricks reach customers worldwide in optimal condition, complying with international standards.Q: How should these bricks be used during installation?

A: During installation, the bricks should be aligned according to the required furnace or kiln design. Due to their standard size and rectangular shape, they can be easily fitted, ensuring maximal coverage and thermal protection.Q: What are the key benefits of choosing these refractory bricks?

A: Key benefits include high fire-retardant efficiency, long-lasting structural integrity, easy installation due to their standard size, and reliable thermal insulation, making them a preferred choice for demanding industrial processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email